home build SAVANNAH S kits

Whether you are a completely new or an advanced build technician, our Savannah Aircraft Build Kits are suitable for you. This is an intense but very rewarding project which will result in Africa’s most loved LSA.

first time builders

Expect to build your first flying machine in 700 to 800 hours.

You will not be disappointed with the end result that is for certain. Also should you run into any issues or need advice during your build we are only a phone call away.

experienced builder

For more experienced builders with practical build experience, excluding painting and upholstery, you can get this aircraft complete in 400 hours. Add another 200 hours for complete paint job. We are always available for direct phone support

KITS

All the Savannah home build kit parts are produced by serial production on CNC and laser-cutting machines, allowing for perfect interchangeability of the spare parts.

All the aluminum skins are cut to size, bent or pressed, drilled and ready to be riveted using the supplied rivets. You only require a little deburring of the components prior to fitting. If you are wondering how long it will take you to build the aircraft here is the answer – For the builder who is practical and good with his (or her) hands:

ESTIMATED BUILDING TIME without painting and upholstery work – 400 hours

With painting and upholstery work – 600 hours

First time builders expect a build time of between – 700 -800 hours

You will not be disappointed with the end result that is for certain. Also should you run into any issues or need advice during your build we are only a phone call away.

KIT #1

Details

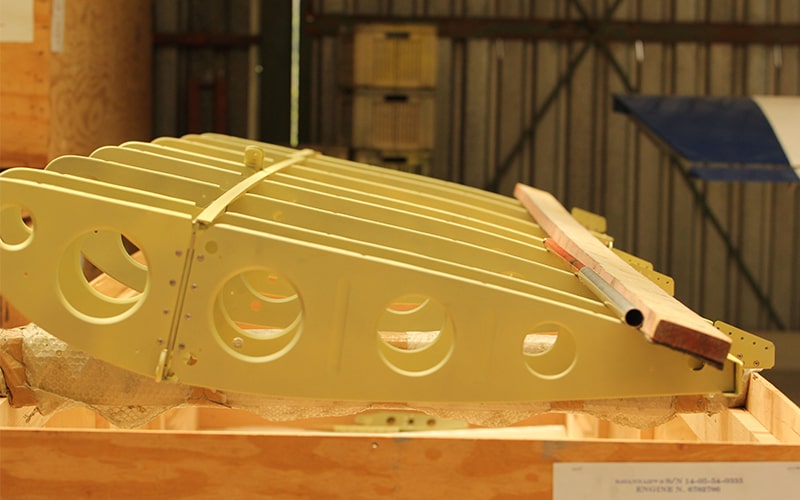

This kit contains all materials necessary to build the fuselage, wings with flaperons, the tail with rudder, stabilizers, elevator trim with servo and wiring harness, wing struts with aerodynamic profile predrilled for perfect alignment, tricycle landing gear, dual rudder pedals, disc brakes, tyres and tubes, pedals, yoke, flaps lever, commands, cables with turnbuckles, guides and mounting brackets, all cables already cut to the right length and crimped with thimbles using certified NICO press equipment.

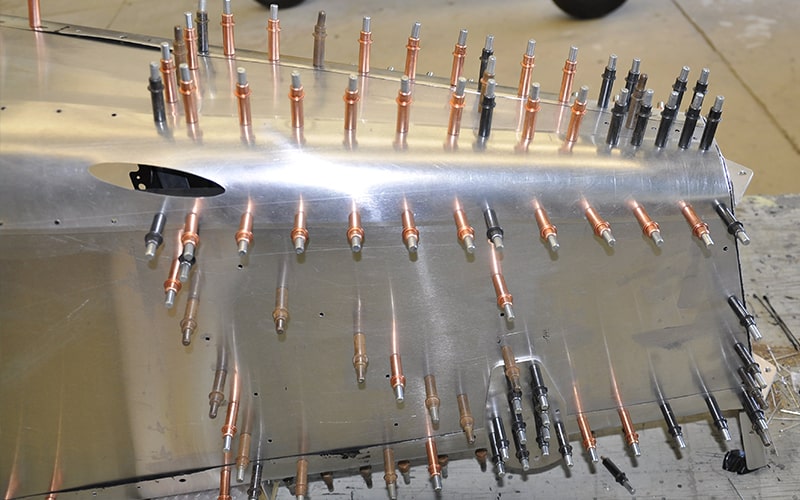

All the parts are produced by serial production on CNC and laser-cutting machines, allowing for perfect interchangeability of the spare parts. All the aluminum skins are cut to size, bent or pressed, drilled and ready to be riveted using the supplied rivets. You only require a little deburring of the components prior to fitting. Even the rivet gun is included in the kit, together with some clecos and their pliers. For a quick and perfect building it is suggested to use about 1500 clecos that can be purchased separately. We will buy the clecos back once your build is complete.

The parts that need to be solid riveted (wing spars, some parts of the fuselage, etc.) are supplied already built in order to simplify the process.

Included in the kit are:

• All AN screw bolts, with nuts and washers

• locking wire

• two wing tanks containing 36 liters (9 gal) each and a reserve tank with ball-cock reserve indicator, condensation drain, fuel tap and tubing to the firewall

• three point safety harness

• dual throttle

• plastic tips for wings, ailerons, slats and tail

• Templates for adjusting ailerons, tail. etc.

The Kit #1 allows you to complete a full functional airframe. To complete the airplane you would need Kit #2 & Kit #3

Kit #2

Details

KIT #2 add on:

Engine mount

Engine cowling

Water and oil radiators

Tubes

Hoses

Fittings

Straps

Padded seats

Instruments

Electrical wiring harness

Upholstery

Elevator trim servo.

kit #3

Details

- KIT #3 add on:

Engine

Exhaust

Propellor

Spinner.

You may purchase the kits in 1, 2 or 3 phases depending on budget and space. For example, purchase a kit 1 to start the build and then later add the kit 2 and 3 as needed or purchase a kit 3 from the get go and have everything you need to complete the full aircraft.